Maintenance Planning Software. Increase productivity by 25%.

Ensure timely upkeep of machinery and equipment with automated, optimized scheduling.

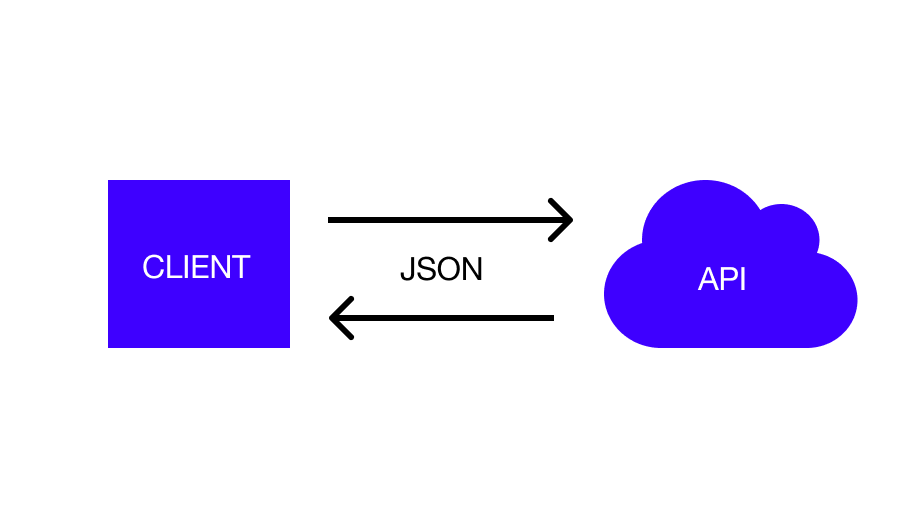

REST API - JSON in/out

Harness the power of AI-driven optimization technology by sending your planning problem to our REST API and we return you an optimized solution. Catering to the complexities of managing maintenance scheduling.

Your preferred way of hosting

Host Timefold on-premise via a docker image and your preferred hosting solution. Or leverage our technology via the Timefold hosted cloud platform.

Features designed for flexibility

- Adapt in real-time to changes in maintenance requests, including urgent requests, workforce availability, change parts availability,...

- Continuous planning, allowing to plan ahead for days, weeks or even months, while only publishing the short term planning.

- Remain in control with manual pinning of specific routes, drivers or vehicles.

For service team owners

Timefold schedules and routes your technicians

Get in touch and learn how efficient route scheduling optimization for your technicians results in an increased bottom line and fuel savings. Automatically create a planning that is adapted to your fleet and technician skills.

Talk to usFor Maintenance Service SaaS

Focus on making the best maintenance software

Timefold optimizes routes for thousands of technicians automatically. Integrate Timefold in your SaaS so you can focus on developing other core-features.

Talk to usOptimized Maintenance Scheduling Routing for your business constraints and rules

Resource Availability

Efficiently allocate staff and equipment based on real-time availability.

Time windows

Schedule tasks flexibly within defined SLA time frames

Maps integration

Seamlessly integrate maps for accurate navigation, ensuring efficient and reliable route planning.

Various vehicle types

Plan and mix different vehicle types to optimize for specific requirements such as size, weight, or specialized equipment.

Technician breaks

Efficiently incorporate breaks. i.e. lunch breaks into routes without compromising delivery schedules.

Technician skills

Assign technicians to jobs based on their skills and expertise to ensure the right person is on the job.

Affinity

Consider customer preferences and establish routes that prioritize visiting locations with higher affinity or priority.

Multi-day completion

Certain jobs can't be finished on the same day. That's when multi-day service completion comes to play.

Task Duration

Adapt schedules to cope with minor variations in task durations.

Maintenance Frequency

Adjust schedules based on specific maintenance intervals per machine.

Shift end limit

Define when the vehicle and technicians have to return to the end-location (home, depot, ...)

Custom constraints?

Your unique business rule can be translated into an actionable constraint.

Maintenance scheduling optimization

18 years of Planning Optimization

18 years ago I started OptaPlanner as an Open Source project and built a team around it, at Red Hat.

Geoffrey De Smet - Co-founder & CTO, Timefold

Now we are continuing the project as a dedicated company under the Timefold brand. Improving on our already existing product, building with the co-creators of OptaPlanner.

Get started with Maintenance Scheduling today!

Ensure timely upkeep of machinery and equipment with automated, optimized scheduling.

Get in touchRelated planning models

Vehicle Routing (VRP)

Determines the most efficient routes for a fleet of vehicles to visit multiple destinations, considering factors like distance, vehicle capacity, time windows, and customer preferences to optimize delivery or service operations.

Read moreJob Shop Scheduling

Allocates resources and schedules production tasks in manufacturing environments with diverse equipment and processes, aiming to minimize idle time, maximize throughput, and meet delivery deadlines.

Read more